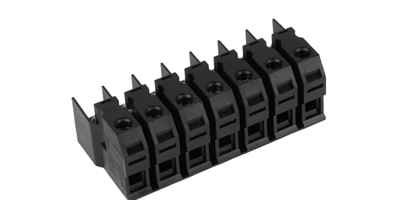

In the vast expanse of electrical connections, the Bar-Type Screw Fastening Terminal Block shines brightly. With its ingenious design and outstanding performance, it provides a solid foundation for circuit construction in numerous industries, embarking on an efficient electrical journey.

I. Introduction

In the intricate web of electrical systems, the Bar-Type Screw Fastening Terminal Block stands as a cornerstone of reliable and efficient wire termination. Its design and functionality have been refined over the years to meet the exacting demands of various industries, from power generation and distribution to industrial automation and consumer electronics. This article delves into its multifaceted aspects, elucidating its design ingenuity, operational prowess, and application versatility.

II. Design and Construction

2.1 Robust Housing Design

The terminal block is encased in a durable, often flame-retardant plastic housing. This housing not only provides electrical insulation but also safeguards the internal components from mechanical damage, dust, and moisture. Its ergonomic shape allows for easy handling and installation, even in confined spaces. The material's choice is crucial, as it must withstand temperature variations, chemical exposure, and physical stress. For instance, in industrial settings where the terminal block may be exposed to oil, solvents, or extreme temperatures, the housing material's resilience ensures uninterrupted performance.

2.2 Precision Screw Mechanism

At the heart of the terminal block lies the screw fastening mechanism. The screws are engineered with high precision, featuring fine threads that ensure a firm grip on the inserted wires. The torque applied during screwing is carefully calibrated to prevent over-tightening, which could damage the wire strands or cause the screw to strip. This mechanism allows for easy wire insertion and removal, facilitating quick connection modifications or repairs. In applications where frequent wire changes are necessary, such as in prototype development or electrical testing laboratories, the screw fastening design proves invaluable.

2.3 Conductive Bar Material

The conductive bar within the terminal block is typically crafted from high-quality metals like copper or copper alloys. These materials offer excellent electrical conductivity, minimizing power losses during current transmission. The bar's surface may be plated with additional conductive materials or treated to enhance corrosion resistance. This is particularly important in environments where humidity or corrosive gases are present, as it maintains the integrity of the electrical connection over time.

III. Operational Advantages

3.1 Secure and Stable Connections

The screw fastening method provides a highly reliable wire connection. Once tightened, the wires are held firmly in place, withstanding vibrations, mechanical shocks, and thermal expansion and contraction. This stability is essential in applications such as motors, generators, and industrial machinery, where any loosening of wires could lead to electrical arcing, equipment failure, or safety hazards.

3.2 Versatility in Wire Gauge Compatibility

Bar-Type Screw Fastening Terminal Blocks can accommodate a wide range of wire gauges. This adaptability makes them suitable for diverse electrical projects, from low-power electronics with fine-gauge wires to high-power industrial applications requiring thick cables. The terminal block's design allows for easy customization of the number of connection points and the spacing between them, catering to specific wiring requirements.

3.3 Ease of Installation and Maintenance

The simplicity of the screw fastening process enables technicians to quickly install and connect wires. Additionally, the terminal block's modular design allows for easy replacement of individual components in case of damage. This reduces downtime and maintenance costs, especially in large-scale electrical installations where quick repairs are crucial.

IV. Applications Across Industries

4.1 Power Generation and Distribution

In power plants and electrical substations, Bar-Type Screw Fastening Terminal Blocks are used to connect power cables, transformers, and switchgear. Their ability to handle high voltages and currents, along with their reliable connection properties, ensures the efficient and safe transmission of electricity across the power grid.

4.2 Industrial Automation

In factories and manufacturing facilities, these terminal blocks play a vital role in connecting sensors, actuators, controllers, and other automation components. Their versatility in wire gauge compatibility and ease of installation support the complex wiring requirements of automated production lines, enabling seamless communication and control between different devices.

4.3 Consumer Electronics

Even in consumer electronics products like home appliances, televisions, and audio equipment, the terminal block finds application in internal wiring. Its compact size and reliable performance contribute to the overall functionality and safety of these devices.

V. Future Trends and Innovations

5.1 Miniaturization and Increased Density

As electronic devices continue to shrink in size, there is a growing demand for smaller and more densely packed terminal blocks. Manufacturers are investing in research and development to reduce the physical dimensions of the terminal blocks while maintaining or improving their electrical performance. This trend is driven by the need to fit more components into limited space, especially in portable and wearable electronics.

5.2 Integration with Smart Technologies

The future of Bar-Type Screw Fastening Terminal Blocks may involve integration with smart sensors and communication modules. These intelligent terminal blocks could monitor parameters such as wire temperature, current flow, and connection integrity in real-time. This data could be transmitted to a central control system for predictive maintenance and performance optimization. Such advancements would enhance the reliability and efficiency of electrical systems, reducing the risk of unexpected failures and downtime.