In the realm of electrical connections, the Quick Plug Wire Terminal shines brightly. It combines cutting-edge technology with ingenious design, reshaping the connection paradigm and opening a new chapter of efficient electricity.

I. Introduction

The Quick Plug Wire Terminal represents a significant leap in electrical connection technology. Its design and construction are meticulously crafted to meet the escalating demands of modern electrical systems, ensuring seamless integration, enhanced safety, and optimal performance.

II. Ergonomic Design Principles

2.1 Streamlined Form Factor

The terminal's outer casing is sculpted with precision to achieve a streamlined profile. This not only facilitates easy insertion into crowded electrical compartments but also minimizes the risk of snagging or interfering with adjacent components. For example, in a densely packed control panel, its compact shape allows for efficient utilization of space without causing congestion.

2.2 Tactile and Visual Aids

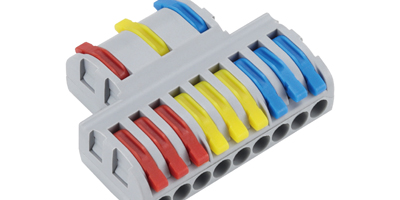

Thoughtful design incorporates tactile markers and visual indicators. These features assist technicians in quickly identifying the correct insertion orientation and ensuring proper alignment. A subtle ridge or groove on the terminal body provides a tactile cue, while color-coded markings or engraved symbols visually communicate connection details. This intuitive design reduces the likelihood of incorrect wire insertion, thereby enhancing installation efficiency and connection reliability.

III. Material Selection and Its Significance

3.1 Conductive Core Materials

High-purity copper alloys form the core of the Quick Plug Wire Terminal. Copper's exceptional electrical conductivity properties ensure minimal resistance, facilitating efficient current flow. This is crucial in applications where power transmission losses must be minimized, such as in high-power industrial machinery or data center power distribution.

3.2 Insulating and Protective Materials

The outer insulation is fabricated from advanced, fire-retardant polymers. These materials not only provide electrical insulation but also safeguard against environmental factors. They possess high resistance to moisture, chemicals, and temperature variations. In outdoor electrical installations or industrial settings with harsh chemical exposures, this insulation prevents electrical leakage and corrosion, prolonging the terminal's operational life.

3.3 Durability Enhancement

Reinforcing agents and stabilizers are incorporated into the plastic materials to enhance their mechanical strength and durability. This enables the terminal to withstand mechanical stresses, such as vibrations in industrial equipment or accidental impacts during installation and maintenance. The combination of robust materials ensures that the terminal maintains its structural integrity and electrical performance over an extended service life.

IV. Internal Mechanism Engineering

4.1 Precision Clamping Mechanism

The internal clamping structure is engineered with micron-level precision. Spring-loaded jaws exert a consistent and controlled force on the inserted wire. This force is calibrated to hold the wire firmly in place while avoiding excessive compression that could damage the wire strands. In applications involving variable mechanical vibrations, such as in automotive electrical systems, this clamping mechanism prevents wire loosening and intermittent electrical failures.

4.2 Anti-Corrosion and Anti-Oxidation Measures

To combat the detrimental effects of oxidation and corrosion, the contact surfaces within the terminal are often plated with noble metals or corrosion-resistant alloys. Gold, silver, or nickel plating provides a protective barrier against oxidation, maintaining low contact resistance over time. Additionally, the design incorporates features that prevent the ingress of moisture and contaminants, further safeguarding the integrity of the electrical connection.

4.3 Sealing and Environmental Protection

Integral seals and gaskets are employed to create a hermetic environment within the terminal. These prevent the intrusion of dust, moisture, and other environmental pollutants. In marine or outdoor applications, where exposure to saltwater spray and humidity is common, the sealed design ensures uninterrupted electrical performance and mitigates the risk of short circuits caused by conductive contaminants.

In conclusion, the design and construction of the Quick Plug Wire Terminal synergistically combine ergonomic design, premium materials, and advanced engineering to deliver a reliable, efficient, and durable electrical connection solution. This innovation is set to redefine the standards of wire termination in diverse electrical applications, from household appliances to complex industrial automation systems.